Second only to tenon replacement, fitting a new stem is probably the most common pipe repair, and for good reason. With a modicum of care, a briar stummel can last for decades or even centuries, but the stem is subjected to more than just heat from burning tobacco. It must also contend with tooth dents, chipped buttons and even chemical wear and tear caused by the interaction between the stem material and the smoker’s saliva.

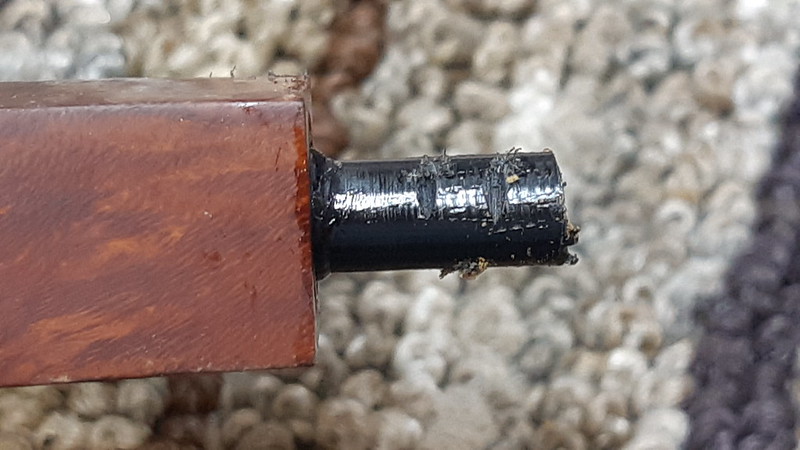

The stem on today’s restoration subject, a Hardcastle’s Deluxe Bulldog, was definitely due for a refresh. At some time in the past, the stem had broken near the button, whether from a fall or from tooth damage, and the pipe’s steward had coaxed a little bit more life out of the stem by cutting off the broken portion and sanding things smooth.

That was some time ago, and as you can see from this initial series of images, the pipe needed a bit of TLC to get back into fighting form. Apart from the obvious stem issues, the pipe needed a good Ream & Clean to remove the old carbon cake from the chamber and clean up the rim.

The pipe is stamped on the left shank with “Hardcastle’s” (arched upwards) over “British Made” over “Deluxe” (arched downwards). On the right shank the pipe is marked “Made in London” over “England”. A shape number, “61” was barely legible on the underside of the shank. I was unable to get a good picture of it.

Before moving ahead with fitting a new stem, the stummel needed to be cleaned. I started the process by reaming the chamber back to briar and tidying up the chamber walls with sandpaper wrapped around a dowel.

Next was to clean away the carbon deposits on the rim surface and tidy up the briar underneath. The rim was in rather good shape under the dirt and carbon, but the inner rim was slightly charred. I cleaned it up with a 320-grit sanding sponge and some 800-grit wet sandpaper.

So far I was making good headway on this project, but I got bogged down at the next step, cleaning the shank and airway. As you can see in the next couple of images, there was a lot of carbon, tar and tobacco debris hiding within the stummel’s internals. It took quite a bit of scrubbing and scraping to get it all out, but patience, 99% isopropyl alcohol and a set of disposable gloves did the trick.

To make sure that all the old tars and their corresponding odours were properly purged from the briar, I set the stummel up with an overnight alcohol treatment, stuffing the shank and chamber with cotton balls and filling the pipe with more 99% isopropyl alcohol.

I let the alcohol work on the pipe overnight, and came back to the shop to find that the previously white cotton wool had turned a dark yellow-brown from absorbing the deep-seated tars and other goodies the alcohol had dissolved over the past 12 hours. I discarded the spent cotton and ran one last pipe cleaner through the airway to remove the last traces of contaminants before setting the stummel aside to air and rest a bit while I prepped the new stem.

This pic shows the original stem below the new Delrin tenon I made up in the shop, replicating the original stepped design.

An appropriately sized drill bit opened up the airway of the precast stem blank and created a mortise into which the new tenon would be glued.

Delrin is a strong but somewhat slippery material, often used to make bushings for industrial machinery. To provide a solid mechanical bond between the tenon and stem, I cut a series of grooves into the stem end of the tenon. I also used my rotary tool to cut a few similar notches on the inside of the stem mortise.

When the prep was complete, I mixed up a small amount of 2-part epoxy and applied some to both the outside of the tenon and the inside of the stem mortise, making sure that the epoxy got pushed down into the grooves I cut previously. A light coat of petroleum jelly on the shank face helps keep any excess epoxy off of the briar.

After sliding the stem onto the end of the tenon, I aligned the stem against the shank face and held it in position for a moment until the epoxy began to grab. Then the pipe was clamped upright in the vise with a few pieces of masking tape to hold the stem in position. I again left the pipe overnight to give the epoxy time to cure properly.

The following day I removed the masking tape and twisted the new stem out of the shank. A quick minute with the drill opened up the airway through the tenon.

Then it was time to size the new stem to the shank. A diamond shank like that on this Bulldog can be a bit finnicky to get just right, but patience, practice and constant checking and rechecking of progress make the job easier. Note the clear hockey tape wrapped around the shank. This protects the briar and the pipe’s nomenclature form damage while I file and sand the new stem to its final dimensions.

The sharp-eyed among you may have already noticed that the new stem was a Diamond Taper, while the original stem was a Diamond Saddle. The pipe’s steward wished to keep the pipe’s appearance as close to original as possible, so the next part of this project was the removal of excess stem material on the top and bottom of the stem to transform the Taper to a Saddle.

When I was happy with the Saddle stem, I hand sanded the entire stem with increasingly finer grits of abrasive, from 220-grit to 2000-grit to remove the file marks and begin to raise the shine. A run on the buffing wheel with Red Tripoli and White Diamond compounds completed the polishing process. I also buffed the stummel and finished the entire pipe with a few layers of Carnauba wax to shine and protect the freshly restored pipe.

This Hardcastle’s Deluxe Bulldog was clearly a favourite of its current steward and I am happy to have been able to return it to him in almost-new condition. I’m sure the pipe will continue to provide many years of smoking companionship.

Thanks for joining me for this estate pipe restoration project. I hope you enjoyed following along. Until next time, Happy Piping!

Here’s the finished pipe.

Absolutely Beautiful !!!! –

LikeLiked by 1 person

Thank you!

LikeLike